Introduction

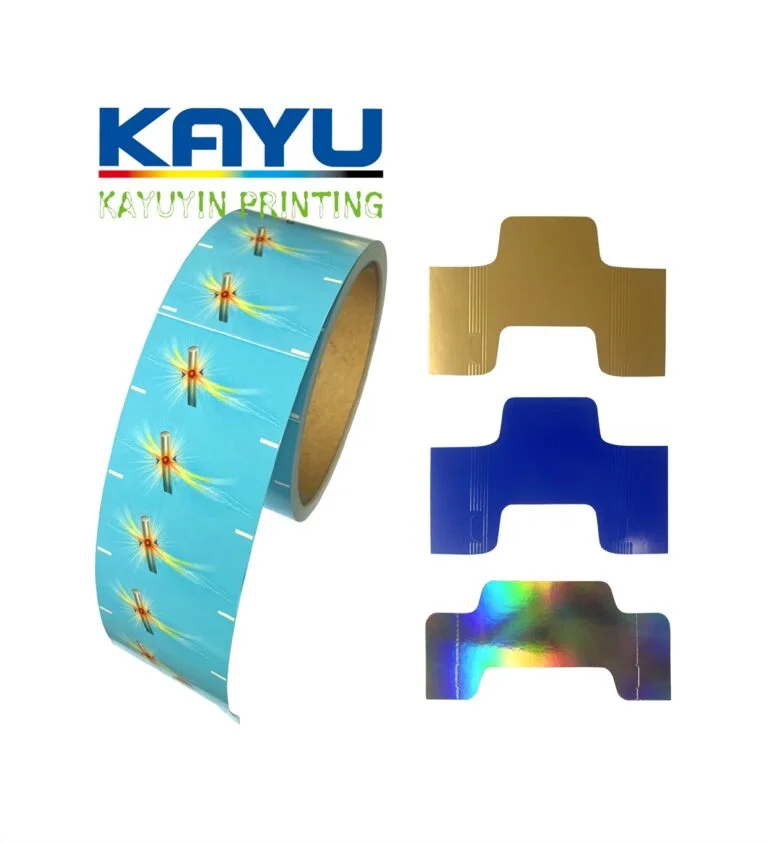

https://kayuyin.com/product/cigarette-inner-frame/ Cigarettes are often viewed as simple consumables, yet their construction is far from basic. At the heart of every cigarette lies the inner frame, a crucial component that ensures structural integrity and optimal smoking experience. This article delves into the details of the cigarette inner frame, exploring its materials, design, and the role it plays in the overall functionality of a cigarette.

The Role of the Cigarette Inner Frame

The inner frame of a cigarette is akin to the skeleton of a building. It provides the necessary support to hold the tobacco in place and maintain the cylindrical shape of the cigarette. Without this component, the cigarette would lack the rigidity required for a consistent smoking experience. The inner frame also helps in controlling the burn rate of the tobacco, ensuring an even and steady combustion.

Materials Used in the Inner Frame

The materials used in the construction of the inner frame are selected with precision to balance functionality and safety. Traditionally, the inner frame is made from a thin, porous paper known as cigarette paper. This paper is designed to be lightweight yet sturdy enough to hold the tobacco blend securely. Additionally, it is treated to regulate the burn rate, ensuring that the cigarette burns evenly from start to finish.

Cigarette Paper Composition

Cigarette paper is primarily made from flax, hemp, or wood pulp. These materials are chosen for their fibrous nature, which provides the necessary strength and flexibility. The paper is also treated with various additives to enhance its performance. These additives can include burn agents, which control the rate at which the cigarette burns, and fillers, which add bulk and improve the paper’s handling characteristics.

Environmental Considerations

In recent years, there has been a growing emphasis on the environmental impact of cigarette production. This has led to the development of more eco-friendly cigarette papers made from sustainable sources. Manufacturers are also exploring alternatives to traditional additives, seeking natural options that are less harmful to the environment.

Design and Engineering of the Inner Frame

The design of the cigarette inner frame is a complex process that involves both engineering and artistry. The goal is to create a structure that supports the tobacco while also enhancing the smoking experience.

Perforations and Ventilation

One of the key features of the inner frame is the inclusion of perforations or ventilation holes. These small openings allow air to mix with the tobacco smoke, reducing the harshness of the inhaled smoke and providing a smoother experience. The placement and size of these perforations are carefully calculated to achieve the desired balance between flavor and smoothness.

Filter Integration

In modern cigarettes, the inner frame also plays a role in integrating the filter. The filter is typically made from cellulose acetate, a type of plastic derived from wood pulp. It is designed to trap tar and other harmful substances, reducing the smoker’s exposure to these toxins. The inner frame must securely hold the filter in place while ensuring that it does not impede the flow of smoke.

The Impact of the Inner Frame on Smoking Experience

The inner frame significantly influences the overall smoking experience. A well-designed inner frame ensures that the cigarette burns evenly, providing a consistent draw from start to finish. It also contributes to the flavor profile of the cigarette by regulating the air-to-smoke ratio.

Consistency and Reliability

Smokers often seek consistency in their smoking experience, and the inner frame plays a crucial role in delivering this. By maintaining the structural integrity of the cigarette, the inner frame ensures that each puff delivers a predictable amount of smoke. This reliability is essential for smokers who have developed specific preferences for their smoking experience.

Flavor and Aroma

The materials and design of the inner frame can also affect the flavor and aroma of the cigarette. For instance, the type of paper used and the presence of additives can influence the taste of the smoke. Manufacturers carefully select materials that complement the tobacco blend, enhancing the overall sensory experience for the smoker.

Innovations and Future Trends

The cigarette industry is constantly evolving, with new innovations aimed at improving the smoking experience and reducing health risks. The inner frame is no exception to this trend, with several advancements in materials and design.

Biodegradable Materials

One of the most significant trends is the development of biodegradable inner frames. These eco-friendly options are designed to break down more quickly than traditional materials, reducing the environmental impact of discarded cigarette butts. Biodegradable filters and papers are already on the market, and ongoing research aims to further improve their performance and sustainability.

Advanced Filtration Techniques

Innovations in filtration technology are also influencing the design of the inner frame. Advanced filters that use activated charcoal or other materials to trap a higher percentage of harmful substances are being integrated into cigarettes. These filters require modifications to the inner frame to ensure proper airflow and structural support.

Customizable Smoking Experience

Another emerging trend is the customization of the smoking experience. Some manufacturers are experimenting with inner frames that allow smokers to adjust the airflow and burn rate of their cigarettes. This customization can be achieved through adjustable perforations or modular components that can be tailored to individual preferences.

Conclusion

The cigarette inner frame is a critical component that often goes unnoticed by consumers. However, its role in maintaining the structural integrity and enhancing the smoking experience cannot be overstated. From the selection of materials to the intricacies of design, every aspect of the inner frame is carefully engineered to deliver a consistent and enjoyable experience. As the industry continues to evolve, innovations in materials and design promise to further enhance the functionality and sustainability of this essential component.