Steel has been a mainstay in the automotive industry since its inception, and its enduring presence is a testament to its unique combination of strength, durability, and affordability. From the early days of the Model T to the advanced vehicles of today, steel has played a critical role in shaping the design, performance, and safety of cars. This article will delve into the world of steel car parts, exploring their diverse applications, the advantages they offer, and the ongoing evolution of this essential material in the automotive landscape.

Steel: A Foundation of Strength and Durability

The inherent strength and durability of steel make it an ideal material for automotive components that must withstand significant stress and wear. Steel’s ability to absorb and distribute impact forces effectively contributes to vehicle safety, particularly in the case of collisions. Its resilience to fatigue and corrosion ensures that car parts remain functional and reliable over long periods of time, even when exposed to harsh environmental conditions.

A Diverse Range of Applications

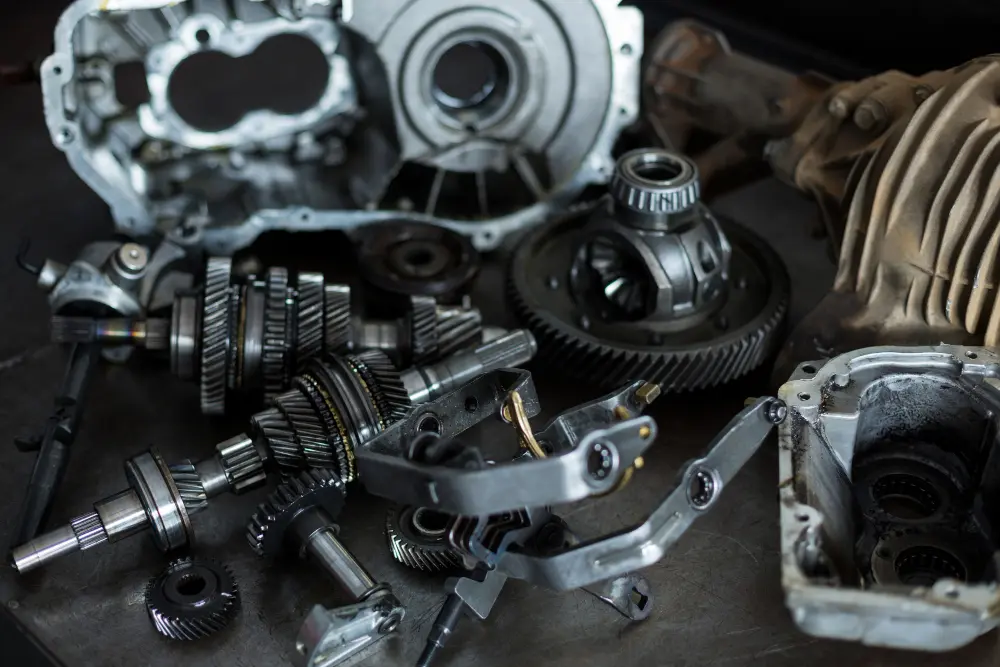

Steel’s versatility allows it to be used in a wide array of car parts, encompassing both structural and functional components.

- Structural Integrity: Steel provides the backbone of a car’s chassis, offering the necessary rigidity and strength to support the entire vehicle. Frames, body panels, and suspension components are often made of steel, ensuring the car’s structural integrity and passenger safety.

- Engine Components: Steel’s ability to withstand extreme temperatures and pressures makes it ideal for critical engine components like crankshafts, connecting rods, and cylinder blocks. These parts are subject to immense forces and heat during operation, and steel’s resilience ensures their long-term performance.

- Safety Features: Steel plays a vital role in enhancing vehicle safety. Brake discs, calipers, and steering components are often made of steel, contributing to reliable and responsive handling. Steel also forms the foundation of safety features like crumple zones, which absorb impact energy during collisions, protecting passengers.

- Wheels and Tires: Steel is a fundamental material in wheel production, with steel rims offering strength and durability. Steel’s inherent strength allows wheels to withstand the forces generated by road contact and braking, ensuring stable and reliable handling.

The Benefits of Steel in Automotive Manufacturing

Beyond its inherent properties, steel offers several key advantages for automotive manufacturers:

- Cost-Effectiveness: Steel is a relatively inexpensive material compared to alternatives like aluminum or composites. This cost-effectiveness makes it a viable option for mass production, making cars more affordable for consumers.

- Ease of Manufacturing: Steel is readily formable and weldable, facilitating efficient and cost-effective production processes. Its adaptability allows manufacturers to create complex shapes and intricate designs, maximizing functionality and aesthetics.

- Recyclability: Steel is a highly recyclable material, promoting sustainability in the automotive industry. Recycling steel reduces the need for virgin materials, minimizing environmental impact and conserving resources.

The Evolution of Steel in Automotive Manufacturing

While steel has long been a cornerstone of automotive production, the industry is constantly evolving, pushing the boundaries of materials science and engineering.

- Advanced Steel Grades: The development of high-strength low-alloy (HSLA) steels has led to significant advancements in strength and weight reduction. These alloys offer greater strength-to-weight ratios, allowing for lighter and more fuel-efficient vehicles without compromising safety.

- Steel Processing Innovations: Advances in steel processing techniques, like cold stamping and laser welding, have enabled manufacturers to create more complex and intricate car parts with greater precision and efficiency. These innovations further optimize performance and reduce waste.

- Hybrid Material Combinations: The automotive industry is increasingly exploring hybrid materials, combining steel with other materials like aluminum or composites to optimize performance. This approach leverages the strengths of different materials, achieving optimal weight reduction, strength, and durability.

Steel’s Continued Importance in the Future of Automotive

Despite the emergence of alternative materials, steel remains a dominant force in the automotive industry. Its inherent strength, durability, and cost-effectiveness make it a valuable asset for manufacturers striving to create safe, reliable, and affordable vehicles.

The ongoing development of advanced steel grades and processing techniques ensures that steel will continue to evolve and adapt to the changing needs of the automotive landscape. As the industry focuses on sustainability and efficiency, steel’s recyclability and potential for weight reduction through advanced alloys solidify its role as a key player in the future of automotive manufacturing.

Steel Products Manufacturer: A Leading Provider of Automotive Components

Steel product manufacturers like Gujrat Steel play a vital role in supplying the automotive industry with high-quality steel components. These manufacturers leverage their expertise in steel processing and manufacturing to produce a wide range of parts, including chassis components, engine components, safety features, and more. Their commitment to quality, efficiency, and innovation ensures that the automotive industry has access to the materials it needs to create durable, safe, and performant vehicles.

Conclusion

Steel’s enduring presence in the automotive industry is a testament to its exceptional properties and its adaptability to evolving industry needs. From structural integrity to safety features, steel plays a critical role in shaping the cars we drive. As the automotive landscape continues to evolve, the innovative development and utilization of steel will remain essential for creating vehicles that are safe, efficient, and sustainable. Steel will continue to be a cornerstone of the automotive industry, ensuring that vehicles are built with strength, durability, and a commitment to the future.